|

Water-filled dams

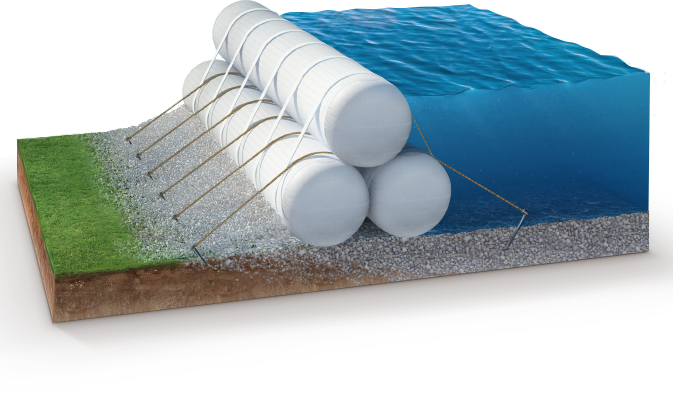

Mobile water-filled dam - a temporary reusable hydraulic structure encloses the waters or territory from the effects of water elements for the protection of residential and industrial buildings from flooding. It consists of one or more soft shells intended for use as flexible prefabricated water obstacles.

MR-GNI Dam Series is a soft, water-filled tank of a polymeric material, length up to 15 m of water-filled dam is provided by tank drain tap DN40. On both sides, the perimeter set straps with eyelets for fixing the dam using ropes on the surface in a strong current.

Part number:

Supplier:

Neftetank LLCDescription

PURPOSE AND BENEFITS WATER-FILLED DAMS

Water-filled dam series MR-GNI produced by "Neftetank" is convenient and easy to use. It is easy to deploy in the field. Special personnel training and use of special equipment are required for installation.

Major advantages over conventional sandbag dams; they save logistic costs:

As a filler for water available in the immediate vicinity in an excess;

Empty elastic shells have low weight, easy to fold and take little space during transportation;

Low labour and human resources.

The water pressure is distributed evenly over the entire surface of the water-filled dam and provides equal force to the whole plane abutting fluid barrier.

In addition, water-filled dams can be used in emergency situations like drying or division of territories under water, for example to increase coastline or divide small area into parts.

WATER-FILLED DAM INSTALLATION CHART

Standard dimensions of water-filled dams are 10 meters long and 1.5 meters wide when empty (when full rise to a height of the order of 0.7 - 0.8 meters). Before filling the water-pressure flexible dams, they are placed on the perimeter of the necessary overlap territory or waters. When this dam set overlap each other and pull together a special sealed between the coupling.

In case of necessary, to increase the stability of the dam elastic tightening the straps together, increasing the overall width of the structure.

Filling the water-filled dams going through the drain-bulk bends Tools motor pump, pump, fire engine, or other means of pumping the required performance. The additional liquid drain pipes during filling must be open in order to bleed the air entering from the injected water flows.

After filling the dam at the drain plugs are screwed liquid outlets and facilities themselves if necessary propped props such as «heel» (or sandbags) in increments of 1 meter for resistance to wave oscillations.

Water-filled dam series MR-GNI produced by "Neftetank" is convenient and easy to use. It is easy to deploy in the field. Special personnel training and use of special equipment are required for installation.

Major advantages over conventional sandbag dams; they save logistic costs:

As a filler for water available in the immediate vicinity in an excess;

Empty elastic shells have low weight, easy to fold and take little space during transportation;

Low labour and human resources.

The water pressure is distributed evenly over the entire surface of the water-filled dam and provides equal force to the whole plane abutting fluid barrier.

In addition, water-filled dams can be used in emergency situations like drying or division of territories under water, for example to increase coastline or divide small area into parts.

WATER-FILLED DAM INSTALLATION CHART

Standard dimensions of water-filled dams are 10 meters long and 1.5 meters wide when empty (when full rise to a height of the order of 0.7 - 0.8 meters). Before filling the water-pressure flexible dams, they are placed on the perimeter of the necessary overlap territory or waters. When this dam set overlap each other and pull together a special sealed between the coupling.

In case of necessary, to increase the stability of the dam elastic tightening the straps together, increasing the overall width of the structure.

Filling the water-filled dams going through the drain-bulk bends Tools motor pump, pump, fire engine, or other means of pumping the required performance. The additional liquid drain pipes during filling must be open in order to bleed the air entering from the injected water flows.

After filling the dam at the drain plugs are screwed liquid outlets and facilities themselves if necessary propped props such as «heel» (or sandbags) in increments of 1 meter for resistance to wave oscillations.