|

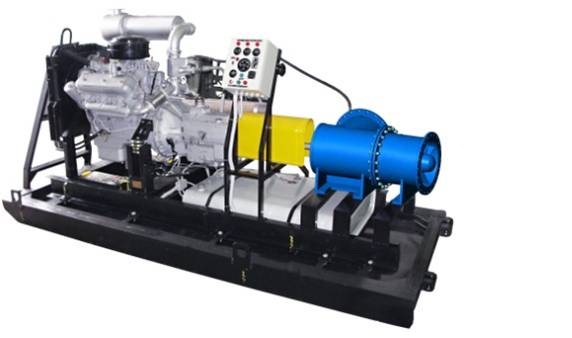

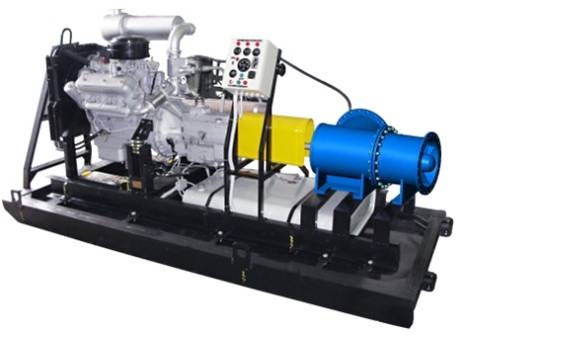

Mobile Diesel Water-Pumping Station SNP

FUNCTION

Mobile water-pumping station SNP-500/10 is designed for outdoor operation, irrigation and drainage works, for pumping water at a temperature ranging from 1 up to 40°С (274-313К), with no solid particles larger than 0,05% by mass and no particles dimensionally larger than 0,2 mm and having a microhardness more than 6,5 GPа (650 kgf/mm2).

Part number:

Supplier:

HMS LivgidromashDescription

DESIGN

Mobile water-pumping station SNP is intended for pumping water and to perform irrigation and drainage work. Water-pumping station is characterized by too high service properties and is reliably operated under temperate and tropical conditions.

The said installation is composed of a diesel-engine drive which incorporates the frame-and-skid mounted power-supply unit consisting of a motor with a power takeoff mechanism. Furthermore, arranged on the frame-skid is a reducing gear which is connected to the power-supply unit by cardan shaft. The frame-and-skid mounted axial pump is also interconnected with the reducing gear (i.e. reducer) through the use of flexible expansion coupling. To control the operation of the pump the branch pipes of the pump are furnished with a pressure gauge (at the pump outlet) and a compound pressure-and-vacuum gauge (at the pump inlet).

In order to fill the pump with water provision is made at the water-pumping station for a gas-jet vacuum apparatus and a disk shutter. The said gas-jet apparatus is installed on the engine outlet manifold just before the silencer and it is operated from the motor exhaust. The gas-jet apparatus is connected by means of the hose pipe and the cock to the casing of the pump. The disk shutter is positioned at the pump outlet. The diesel-engine drive is equipped by air inlet system having an air strainer, by exhaust system accompanied with an exhaust silencer, by cooling system involving a water radiator and oil cooler, by fuel system including a fuel tank and a coarse fuel filter, by electric equipment system with control panel and by clutch release lever. The time-taking of the motor operation is ensured by accumulated hour meter.

At the Customer's request the diesel pump unit may be manufactured in different modifications: on the frame, on the skids, wheeled chassis.

The controlling system of the water-pumping station suits to the 1st degree of automation as per GOST 14228-80 and includes the next following functions: starting-up, control feature, automatic speed control, battery recharging operation and emergency shutdown control of the diesel engine.

TO MONITOR THE OPERATION OF THE ENGINE THE CONTROL PANEL IS FURNISHED WITH:

ammeter in order to control the accumulator storage battery charging;

coolant temperature gauge indicator;

oil-pressure indicator;

tachometer to control the motor speed of rotation;

fuel level indicator;

signaling lamps to indicate the oil pressure & water temperature emergency situations, the clogging up of the oil filter.

The pumping station is provided with automatic protection system against emergency operation, owing to which the constant monitoring over its operation is not required.

The system of emergency & attention signaling and protection on abnormal parameters includes sensors of emergency oil-pressure and critical temperature of the coolant together with emergency lights.

EXAMPLE OF STANDARD DELIVERY SET OF SERIAL INSTALLATIONS SNP 500-10:

Frame-skid.

Diesel engine accompanied with power takeoff mechanism.

Block group of radiators.

Fuel tank.

Fuel pipelines.

Gas-jet vacuum apparatus.

Exhaust pipelines.

Control system of the water-pumping station.

System of emergency-warning signaling & protection against critical parameters.

Cardan shaft.

Reducing gear.

Shelter to protect against precipitations.

Pump ОG-50.

Adapter connectors of the disk shutter.

Disk-shaped shutter.

Suction line (at the Customer's request).

Delivery line (at the Customer's request)

APPLICATION

irrigation, watering of farmlands

drainage, dewatering works

fire-fighting systems

DESIGN FEATURES AND BENEFITS

wide range of applications (irrigation, watering, fire-extinguishing systems and so on);

rapid bringing into service;

possibility to regulate the capacity and head by varying the number of engine rpm;

different design of the unit, namely, on the wheeled chassis or on the skids makes provision for mobility and allows to change quickly the place of installation;

wide range of home-made pumping equipment, suitable for broad selection of parameters to be required;

completeness with diesel engines, both the Russian-made engines and the engines of import production according to the Customer's choice

availability of in-house unique computerized test bench to check parameters and serviceability of the unit as a whole

Mobile water-pumping station SNP is intended for pumping water and to perform irrigation and drainage work. Water-pumping station is characterized by too high service properties and is reliably operated under temperate and tropical conditions.

The said installation is composed of a diesel-engine drive which incorporates the frame-and-skid mounted power-supply unit consisting of a motor with a power takeoff mechanism. Furthermore, arranged on the frame-skid is a reducing gear which is connected to the power-supply unit by cardan shaft. The frame-and-skid mounted axial pump is also interconnected with the reducing gear (i.e. reducer) through the use of flexible expansion coupling. To control the operation of the pump the branch pipes of the pump are furnished with a pressure gauge (at the pump outlet) and a compound pressure-and-vacuum gauge (at the pump inlet).

In order to fill the pump with water provision is made at the water-pumping station for a gas-jet vacuum apparatus and a disk shutter. The said gas-jet apparatus is installed on the engine outlet manifold just before the silencer and it is operated from the motor exhaust. The gas-jet apparatus is connected by means of the hose pipe and the cock to the casing of the pump. The disk shutter is positioned at the pump outlet. The diesel-engine drive is equipped by air inlet system having an air strainer, by exhaust system accompanied with an exhaust silencer, by cooling system involving a water radiator and oil cooler, by fuel system including a fuel tank and a coarse fuel filter, by electric equipment system with control panel and by clutch release lever. The time-taking of the motor operation is ensured by accumulated hour meter.

At the Customer's request the diesel pump unit may be manufactured in different modifications: on the frame, on the skids, wheeled chassis.

The controlling system of the water-pumping station suits to the 1st degree of automation as per GOST 14228-80 and includes the next following functions: starting-up, control feature, automatic speed control, battery recharging operation and emergency shutdown control of the diesel engine.

TO MONITOR THE OPERATION OF THE ENGINE THE CONTROL PANEL IS FURNISHED WITH:

ammeter in order to control the accumulator storage battery charging;

coolant temperature gauge indicator;

oil-pressure indicator;

tachometer to control the motor speed of rotation;

fuel level indicator;

signaling lamps to indicate the oil pressure & water temperature emergency situations, the clogging up of the oil filter.

The pumping station is provided with automatic protection system against emergency operation, owing to which the constant monitoring over its operation is not required.

The system of emergency & attention signaling and protection on abnormal parameters includes sensors of emergency oil-pressure and critical temperature of the coolant together with emergency lights.

EXAMPLE OF STANDARD DELIVERY SET OF SERIAL INSTALLATIONS SNP 500-10:

Frame-skid.

Diesel engine accompanied with power takeoff mechanism.

Block group of radiators.

Fuel tank.

Fuel pipelines.

Gas-jet vacuum apparatus.

Exhaust pipelines.

Control system of the water-pumping station.

System of emergency-warning signaling & protection against critical parameters.

Cardan shaft.

Reducing gear.

Shelter to protect against precipitations.

Pump ОG-50.

Adapter connectors of the disk shutter.

Disk-shaped shutter.

Suction line (at the Customer's request).

Delivery line (at the Customer's request)

APPLICATION

irrigation, watering of farmlands

drainage, dewatering works

fire-fighting systems

DESIGN FEATURES AND BENEFITS

wide range of applications (irrigation, watering, fire-extinguishing systems and so on);

rapid bringing into service;

possibility to regulate the capacity and head by varying the number of engine rpm;

different design of the unit, namely, on the wheeled chassis or on the skids makes provision for mobility and allows to change quickly the place of installation;

wide range of home-made pumping equipment, suitable for broad selection of parameters to be required;

completeness with diesel engines, both the Russian-made engines and the engines of import production according to the Customer's choice

availability of in-house unique computerized test bench to check parameters and serviceability of the unit as a whole