|

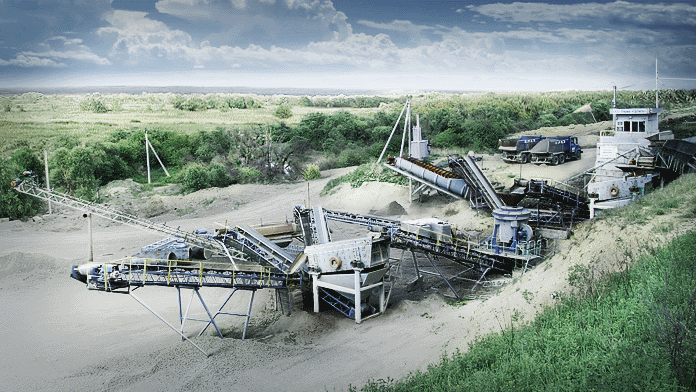

Stationary cubiform crushed stone production lines

Ideal for production of the fractionated cubiform crushed stone from most types of rocks.

Part number:

Description

Standard stationary lines of medium and low capacity presented in this section are the ideal choice for production of the fractionated cubiform crushed stone from most types of rocks (sand and gravel mix, pebble stone) and reproduction of coarse fractions of the produced / supplied crushed stone.

Lines are complete turn-key solutions that may be deployed on a relatively smooth ground or integrated into operational production facilities and infrastructure.

Full-cycle processing lines are designed and projected on the basis of the processed material’s type and characteristics, its mining conditions, requirements to the finished product, and the deployment site.

Specific characteristics of the raw material sometimes require the development of a process procedure instruction and preliminary material testing before the project development. It helps to prevent technological risks connected with the incorrect choice of the main equipment and material flow distribution.

Stationary line (-600 mm; 100-300 t/h)

Stationary line for production of the fractionated 1st class cubiform crushed stone, fine crushed stone and artificial sand.

The line is based on a universal three-stage technology of rock mass reprocessing, equipped with ACS, aspiration system, and additional section for crushing screenings reprocessing (of 0-5 mm class).

Stationary line (-300 mm; 100-300 t/h)

Stationary line for reprocessing of the cobble roundstone and hard rocks with the fineness of up to 300 mm. Line products: fractionated 1st class cubiform crushed stone with the dust-like components content in +5 mm classes of no more than 1.5%.

Sand and gravel mix reprocessing with the help of the line allows producing the following materials:

1st class cubiform crushed stone with the crushed grain content of no less than 92%.

impure sand and gravel mix (clay and exogenic inclusions): class of 0-5 will be the screenings. Production of the pure 0-5 class requires the installation of an additional screening unit.

fine classes of products with the crushed grain content of no less than 90%, which considerably exceeds the requirements of GOST (Russian National Standard) 8267-93 (88%). It is possible due to the use of a DC crusher in the line.

The line is based on a compact two-stage principle of rock mass reprocessing with cyclic loading of crushers, equipped with ACS and passive dust prevention system.

Two-stage crushing helps to considerably reduce the dimensions and cost of the line without prejudice to its operational characteristics.

Lines are complete turn-key solutions that may be deployed on a relatively smooth ground or integrated into operational production facilities and infrastructure.

Full-cycle processing lines are designed and projected on the basis of the processed material’s type and characteristics, its mining conditions, requirements to the finished product, and the deployment site.

Specific characteristics of the raw material sometimes require the development of a process procedure instruction and preliminary material testing before the project development. It helps to prevent technological risks connected with the incorrect choice of the main equipment and material flow distribution.

Stationary line (-600 mm; 100-300 t/h)

Stationary line for production of the fractionated 1st class cubiform crushed stone, fine crushed stone and artificial sand.

The line is based on a universal three-stage technology of rock mass reprocessing, equipped with ACS, aspiration system, and additional section for crushing screenings reprocessing (of 0-5 mm class).

Stationary line (-300 mm; 100-300 t/h)

Stationary line for reprocessing of the cobble roundstone and hard rocks with the fineness of up to 300 mm. Line products: fractionated 1st class cubiform crushed stone with the dust-like components content in +5 mm classes of no more than 1.5%.

Sand and gravel mix reprocessing with the help of the line allows producing the following materials:

1st class cubiform crushed stone with the crushed grain content of no less than 92%.

impure sand and gravel mix (clay and exogenic inclusions): class of 0-5 will be the screenings. Production of the pure 0-5 class requires the installation of an additional screening unit.

fine classes of products with the crushed grain content of no less than 90%, which considerably exceeds the requirements of GOST (Russian National Standard) 8267-93 (88%). It is possible due to the use of a DC crusher in the line.

The line is based on a compact two-stage principle of rock mass reprocessing with cyclic loading of crushers, equipped with ACS and passive dust prevention system.

Two-stage crushing helps to considerably reduce the dimensions and cost of the line without prejudice to its operational characteristics.