|

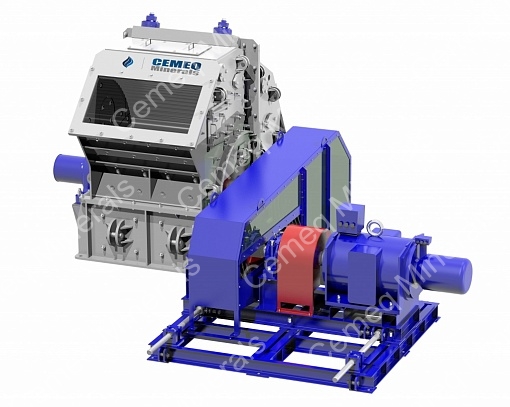

Rotary crushers

Rotary crushers are intended for impact crushing of different materials.

Part number:

Supplier:

CEMEQ Minerals LLCDescription

Rotary crushers are intended for impact crushing of different materials. These crushers are used in various industries. They are used for preparation of concrete aggregates of different sedimentary and extrusive rocks; for crushing of blast-furnace slag, including slag containing metallic inclusions; for crushing of raw materials and clinker in the process of cement production; for crushing of lime, gypsum, marble, broken brick, fireclay refractory; for crushing of glass scrap; for crushing of coking coal; for crushing of ore material, etc. Rotary crushers are used for both primary and subsequent stages of crushing, up to the stage of fine grinding.

The crushers have a solid rotor where removable impact bars are fixed rigidly. The impact bars are made of wear-resistant steel.

In the covers of the upper part of the housing there are baffle plates. The plates are pivoted to spring suspension to provide adjusting of the output slit and to prevent the crusher from breakdown because of the ingress of some not crushable substance.

The crushers are provided with changeable pulleys to adjust the rotor speed that makes it possible to keep the characteristics of the finished product on the required level.

The crushers have a solid rotor where removable impact bars are fixed rigidly. The impact bars are made of wear-resistant steel.

In the covers of the upper part of the housing there are baffle plates. The plates are pivoted to spring suspension to provide adjusting of the output slit and to prevent the crusher from breakdown because of the ingress of some not crushable substance.

The crushers are provided with changeable pulleys to adjust the rotor speed that makes it possible to keep the characteristics of the finished product on the required level.