|

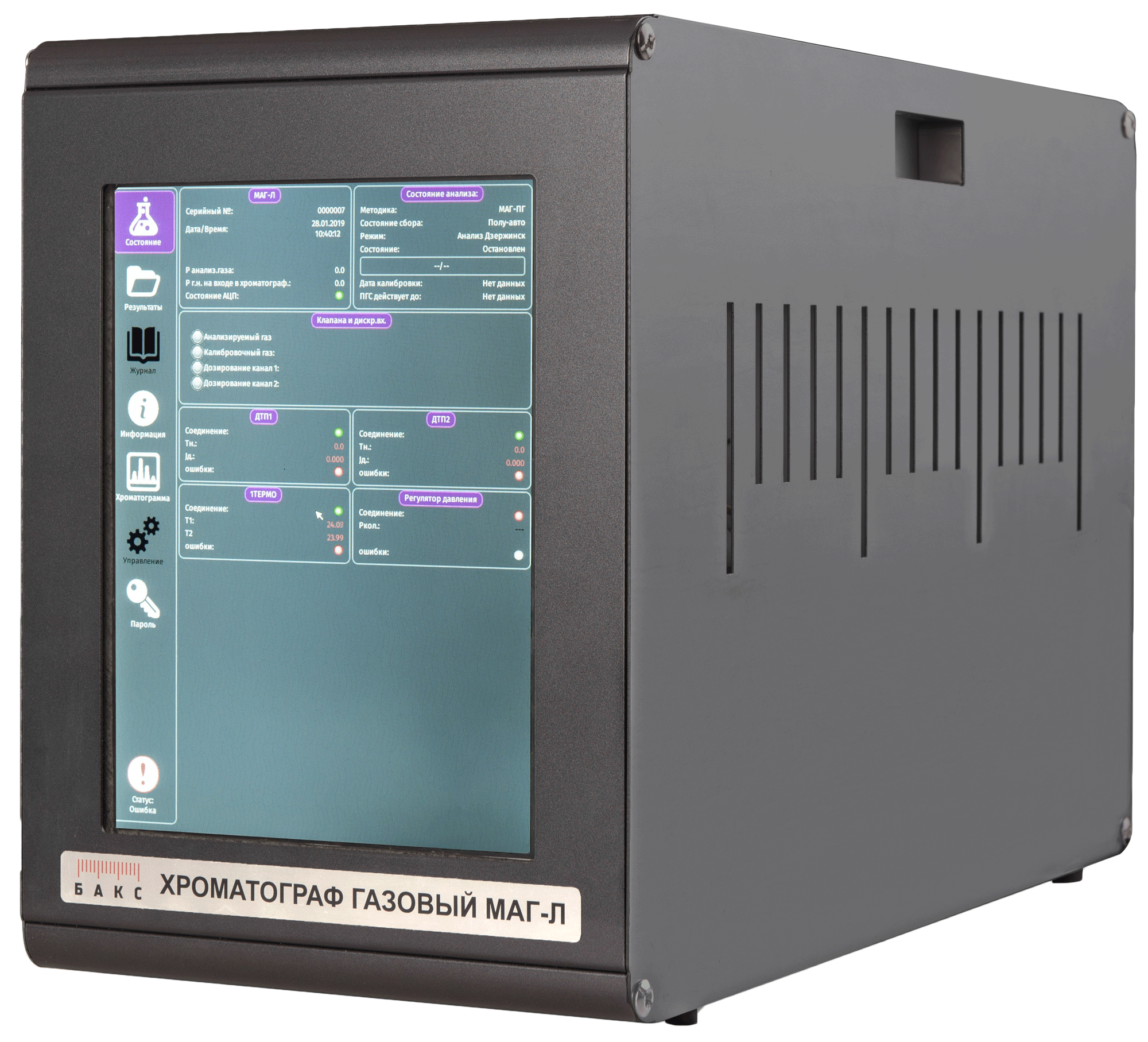

MAG PROCESS GAS CHROMATOGRAPH

MAG process gas chromatograph is designed for automatic analysis of various fluids in the refining, chemical, petrochemical and other industries.

Setting up the analysis conditions, collecting, processing chromatographic data, processing and storage of the results of the analyzes is carried out using the embedded software.

MAG GC can include up to 4 independently thermostatically controlled channels. Each channel consists of 1 detector, 1 metering valve with the possibility of backup flash and a column system suitable for a particular application.Flexible modular design allows you to select the appropriate configuration for a wide range of analytical tasks.

Part number:

Supplier:

STF "BACS" LLCDescription

Modifications of MAG Process Gas Chromatographs :

1. MAG-S PROCESS GAS CHROMATOGRAPH КС 50.310-000-01 FOR ANALYSIS OF SULFUR COMPOUNDS IN NATURAL GAS

The explosion-proof process gas chromatograph for natural gas is designed for the continuous automatic measurement of the mole fraction of combustible natural gas (CNG) components in accordance with GOST 31371.7-2008 (ISO 6974), Methods A and B, followed by calculation of the component values of the composition variables of the calorific value, relative and absolute density, compressibility factor and Wobbe index under GOST 31369-2008 (ISO 6976).

APPLICATIONS

Process gas chromatograph MAG for natural gas analysis system can be used in commercial accounting and monitoring gas quality at the gas metering and gas distribution stations, automatic control systems and process control refineries, petrochemical, and other gas processing plants.

FEATURES

Backflush of C6 + 5 min;

Flow rate of carrier gas is up to 12 ml / min;

Additionally, for natural gas it is possible to analyze:

Methanol;

Helium and hydrogen;

Extended hydrocarbon composition with the hydrocarbon dew point calculation.

Analysis of natural gas of variable and extended (by certified measurement methods).

Can be manufactured in a laboratory based design.

2. MAG PROCESS GAS CHROMATOGRAPH КС 50.310-000-01 FOR ANALYSIS OF LIQUEFIED HYDROCARBONS

This gas chromatograph in explosion-proof design is intended for on-line automatic measurement of the content of organic and non-organic matter in gas mixtures, liquefied gases and liquids.

FEATURES

Analyzed fluid - gas, liquefied gases, liquid;

Flexible modular design allows you to adapt the chromatograph for a wide range of tasks (up to 4 independent analytical channels).

APPLICATIONS

Quality control of natural gas and LNG, including:

Analysis of natural gas according to GOST 37371.7-2008, LNG and BOG according to GOST R 56835-2015;

Analysis of natural gas of variable and extended composition according to certified measurement procedures;

Analysis of sulfur-containing compounds in natural gas according to GOST R 53367-2009;

Control of the natural gas and LPG processing, including:

Analysis of helium concentrate, control of helium membrane treatment process;

Analysis of NGL and liquefied hydrocarbon gases in gas fractionation plants;

Control of natural gas and LPG desulfurization processes at GPPs;

Determination of methanol and other oxygenates in various hydrocarbon fluids;

Control of technological processes in petrochemistry, including:

Control of olefins production (analysis of ethylene, propylene, butylene fractions);

Control of production of MTBE and TAME (analysis of hydrocarbons, ethers, alcohols);

Analysis of process flows and product sales in the production of rubbers;

Control the quality of various products of organic synthesis, including alcohols, glycols, ethers and esters, aldehydes, ketones, fatty acids, etc.;

Flow measurements in various industries, including:

Analysis of various volatile organic compounds, including plant emissions;

Analysis of synthesis gas, coal gasification products, biogas, pyrolysis products;

Analysis of hydrogen-containing gas;

Analysis of permanent gases (He, H2, N2, O2, CO, CO2).

The above list is not limiting. To clarify the possibility of using MAG GS to solve a specific analytical task, it is necessary to fill in the data sheet.

Can be manufactured in a laboratory based design.

OPTIONAL

Liquid sample injector:

External heated sampling valve or injector-vaporizer provides direct introduction of vaporized liquid sample into analytical column without any losses of analyzed compounds. Maximum temperature of the injector is 220°C.

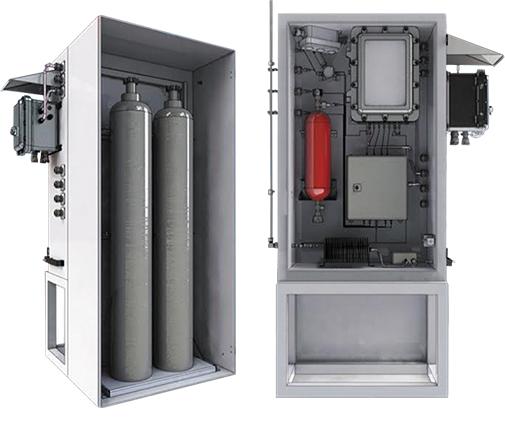

Heated cabinet:

MAG GC can be accommodated into a heated cabinet instead of using block-box which is more cost-efficient solution. The cabinet includes everything that is needed for GC: sample conditioning system, calibration gas cylinder, cylinders with carrier gas, controlled heating and lighting systems.

3. MAG-S PROCESS GAS CHROMATOGRAPH КС 50.360-000 FOR ANALYSIS OF SULFUR COMPOUNDS IN NATURAL GAS

This explosion-proof chromatograph is designed for on-line automatic measurement of the mass concentration of sulfur-containing compounds in combustible natural gas (CNG) in accordance with GOST R 53367-2009 with subsequent calculation of the total and mercaptan sulfur content.

FEATURES

Selective ECD detector;

Carrier gas - compressed air;

Detection limit - from 0.01 ppm (H2S);

Hydrocarbons do not affect the analysis;

Linear characteristic: calibration by 1 CGM;

Wide measurement range.

Can be manufactured in a laboratory based design.

METROLOGICAL PERFORMANCE

Measurement ranges and the values of the relative expanded uncertainty of the measurement result of the mass concentration of sulfur-containing components in the analyzed sample correspond to GOST R 53367-2009 “Combustible natural gas. Determination of sulfur-containing components using chromatographic method”.

1. MAG-S PROCESS GAS CHROMATOGRAPH КС 50.310-000-01 FOR ANALYSIS OF SULFUR COMPOUNDS IN NATURAL GAS

The explosion-proof process gas chromatograph for natural gas is designed for the continuous automatic measurement of the mole fraction of combustible natural gas (CNG) components in accordance with GOST 31371.7-2008 (ISO 6974), Methods A and B, followed by calculation of the component values of the composition variables of the calorific value, relative and absolute density, compressibility factor and Wobbe index under GOST 31369-2008 (ISO 6976).

APPLICATIONS

Process gas chromatograph MAG for natural gas analysis system can be used in commercial accounting and monitoring gas quality at the gas metering and gas distribution stations, automatic control systems and process control refineries, petrochemical, and other gas processing plants.

FEATURES

Backflush of C6 + 5 min;

Flow rate of carrier gas is up to 12 ml / min;

Additionally, for natural gas it is possible to analyze:

Methanol;

Helium and hydrogen;

Extended hydrocarbon composition with the hydrocarbon dew point calculation.

Analysis of natural gas of variable and extended (by certified measurement methods).

Can be manufactured in a laboratory based design.

2. MAG PROCESS GAS CHROMATOGRAPH КС 50.310-000-01 FOR ANALYSIS OF LIQUEFIED HYDROCARBONS

This gas chromatograph in explosion-proof design is intended for on-line automatic measurement of the content of organic and non-organic matter in gas mixtures, liquefied gases and liquids.

FEATURES

Analyzed fluid - gas, liquefied gases, liquid;

Flexible modular design allows you to adapt the chromatograph for a wide range of tasks (up to 4 independent analytical channels).

APPLICATIONS

Quality control of natural gas and LNG, including:

Analysis of natural gas according to GOST 37371.7-2008, LNG and BOG according to GOST R 56835-2015;

Analysis of natural gas of variable and extended composition according to certified measurement procedures;

Analysis of sulfur-containing compounds in natural gas according to GOST R 53367-2009;

Control of the natural gas and LPG processing, including:

Analysis of helium concentrate, control of helium membrane treatment process;

Analysis of NGL and liquefied hydrocarbon gases in gas fractionation plants;

Control of natural gas and LPG desulfurization processes at GPPs;

Determination of methanol and other oxygenates in various hydrocarbon fluids;

Control of technological processes in petrochemistry, including:

Control of olefins production (analysis of ethylene, propylene, butylene fractions);

Control of production of MTBE and TAME (analysis of hydrocarbons, ethers, alcohols);

Analysis of process flows and product sales in the production of rubbers;

Control the quality of various products of organic synthesis, including alcohols, glycols, ethers and esters, aldehydes, ketones, fatty acids, etc.;

Flow measurements in various industries, including:

Analysis of various volatile organic compounds, including plant emissions;

Analysis of synthesis gas, coal gasification products, biogas, pyrolysis products;

Analysis of hydrogen-containing gas;

Analysis of permanent gases (He, H2, N2, O2, CO, CO2).

The above list is not limiting. To clarify the possibility of using MAG GS to solve a specific analytical task, it is necessary to fill in the data sheet.

Can be manufactured in a laboratory based design.

OPTIONAL

Liquid sample injector:

External heated sampling valve or injector-vaporizer provides direct introduction of vaporized liquid sample into analytical column without any losses of analyzed compounds. Maximum temperature of the injector is 220°C.

Heated cabinet:

MAG GC can be accommodated into a heated cabinet instead of using block-box which is more cost-efficient solution. The cabinet includes everything that is needed for GC: sample conditioning system, calibration gas cylinder, cylinders with carrier gas, controlled heating and lighting systems.

3. MAG-S PROCESS GAS CHROMATOGRAPH КС 50.360-000 FOR ANALYSIS OF SULFUR COMPOUNDS IN NATURAL GAS

This explosion-proof chromatograph is designed for on-line automatic measurement of the mass concentration of sulfur-containing compounds in combustible natural gas (CNG) in accordance with GOST R 53367-2009 with subsequent calculation of the total and mercaptan sulfur content.

FEATURES

Selective ECD detector;

Carrier gas - compressed air;

Detection limit - from 0.01 ppm (H2S);

Hydrocarbons do not affect the analysis;

Linear characteristic: calibration by 1 CGM;

Wide measurement range.

Can be manufactured in a laboratory based design.

METROLOGICAL PERFORMANCE

Measurement ranges and the values of the relative expanded uncertainty of the measurement result of the mass concentration of sulfur-containing components in the analyzed sample correspond to GOST R 53367-2009 “Combustible natural gas. Determination of sulfur-containing components using chromatographic method”.

Specification

1. MAG_GC_Brochure.pdf2. МАГ_2019.pdf

.jpg)