|

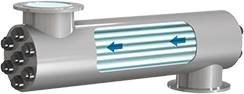

UV systems for water disinfection

LIT offers a wide range of UV disinfection systems for natural, industrial, waste- and other water applications with various capacities depending on the project specific water quality, the required disinfection level and the operational conditions.

Part number:

Supplier:

LITDescription

A wide range of LIT equipment is certified according to international accepted standards: ÖVGW (Austria), DVGW (Germany), USEPA (USA).

The LIT UV equipment automation and controls are based on state-of-the-art microprocessor systems of renowned brands like VIPA, SIEMENS, Schneider Electric and can be adapted to the customer specific requirements. LIT UV systems are equipped with UV intensity sensors manufactured by LIT or third party. Validated UV intensity sensors manufactured by renowned global manufacturers. All LIT equipment (except for ultra-small systems) has a dose pacing system, to optimize the power consumption. LIT applies effective chemical cleaning and/or automatic mechanical wiping systems for the various equipment type, cleaning requirements depend on operational conditions and client’s request.

LIT produces four groups of UV disinfection system for a wide range of water qualities and applications: DUV, DUV Pro, MLP, MLV.

The distribution of the UV intensity field in the UV reactor, hydraulic distribution and equalizing system determine the disinfection efficiency and operational reliability of the UV disinfection system. The equipment design of LIT UV units considers all the above water parameters and operational conditions for different water volumes and water types.

The product groups DUV, DUV Pro, MLP, MLV of LIT UV equipment are divided into series A, B, E, F, G, K, N to match application specific conditions and characteristic water qualities to be disinfected. Each series is optimized for a specific range of UV transmittances to provide maximum UV disinfection efficiency at minimum head loss.

The LIT UV equipment automation and controls are based on state-of-the-art microprocessor systems of renowned brands like VIPA, SIEMENS, Schneider Electric and can be adapted to the customer specific requirements. LIT UV systems are equipped with UV intensity sensors manufactured by LIT or third party. Validated UV intensity sensors manufactured by renowned global manufacturers. All LIT equipment (except for ultra-small systems) has a dose pacing system, to optimize the power consumption. LIT applies effective chemical cleaning and/or automatic mechanical wiping systems for the various equipment type, cleaning requirements depend on operational conditions and client’s request.

LIT produces four groups of UV disinfection system for a wide range of water qualities and applications: DUV, DUV Pro, MLP, MLV.

The distribution of the UV intensity field in the UV reactor, hydraulic distribution and equalizing system determine the disinfection efficiency and operational reliability of the UV disinfection system. The equipment design of LIT UV units considers all the above water parameters and operational conditions for different water volumes and water types.

The product groups DUV, DUV Pro, MLP, MLV of LIT UV equipment are divided into series A, B, E, F, G, K, N to match application specific conditions and characteristic water qualities to be disinfected. Each series is optimized for a specific range of UV transmittances to provide maximum UV disinfection efficiency at minimum head loss.