|

Horizontal pumping station

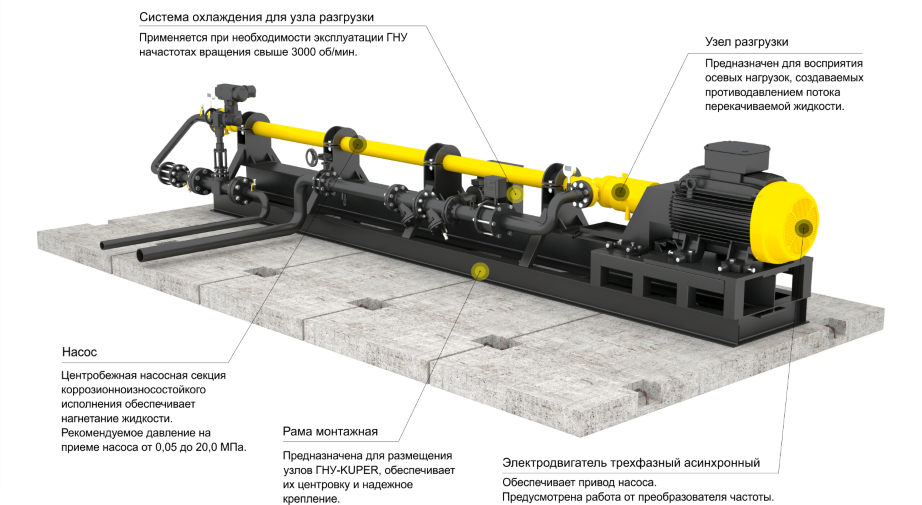

Horizontal Pumping Station is designed to inject the fluid into wells to maintain reservoir pressure of oil wells, disposal of produced water.

Part number:

Supplier:

LLC KuperDescription

Horizontal Pumping Station (HPS) consists of a frame, an electric engine, a thrust(discharge) and a receiving chamber, the pump section, the multiplier (if necessary) and oil-cooled radiators. HPS completed with a vibration sensor, sensors of liquid pressure in the supply and discharge pipelines, temperature sensors of a resistant camera and a pump section. HPS may include a control station (CS) based on logical controller microprocessor completed with frequency drive (FD) or a soft starter

The features of the installation is:

pump section with the working attachment of high-strength corrosion-proof cast iron such as "Ni-Resist" or stainless steel;

high-strength and high-accuracy shafts and pump sections are made of stainless steel or alloy "K-Monel";

radial bearings of the pump are made of zirconium carbide or tungsten carbide and silicon carbide;

the usage of mechanical face seals including double seals which provide tightness of the system at the time of pressure at the reception of pump up to 4.0 MPa;

pumping stations equip with three-phase asynchronous engines with a rotation speed of 3000 rpm and a supply voltage of 380V, 660V or 3.0 / 6.0 / 10.0 kV, the execution according to the protection degree IP-54, electric engines are equipped with bearings by leading manufacturers such as SKF and FAG. At the request of the Customer an electric engine can be equipped with temperature sensors of front and rear bearings, stator temperature, and performance of explosion protection can be 1ExdIIBT4.

The features of the installation is:

pump section with the working attachment of high-strength corrosion-proof cast iron such as "Ni-Resist" or stainless steel;

high-strength and high-accuracy shafts and pump sections are made of stainless steel or alloy "K-Monel";

radial bearings of the pump are made of zirconium carbide or tungsten carbide and silicon carbide;

the usage of mechanical face seals including double seals which provide tightness of the system at the time of pressure at the reception of pump up to 4.0 MPa;

pumping stations equip with three-phase asynchronous engines with a rotation speed of 3000 rpm and a supply voltage of 380V, 660V or 3.0 / 6.0 / 10.0 kV, the execution according to the protection degree IP-54, electric engines are equipped with bearings by leading manufacturers such as SKF and FAG. At the request of the Customer an electric engine can be equipped with temperature sensors of front and rear bearings, stator temperature, and performance of explosion protection can be 1ExdIIBT4.