|

For Horizontal Wells Stimulated with Multistage Hydraulic Fracturing

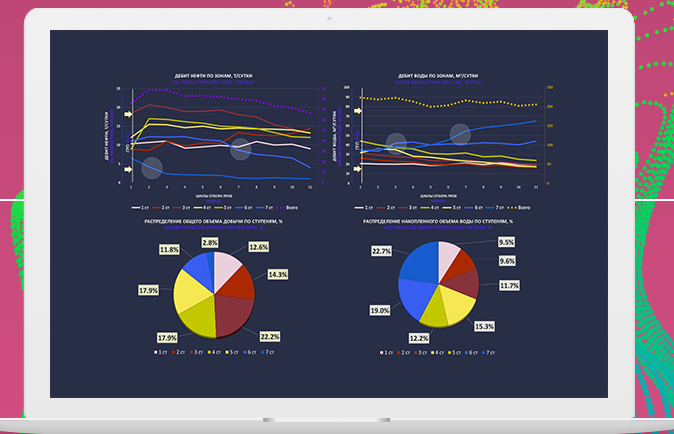

The project begins by collaborating with the customer to determine the scope of their needs and is completed with the issuance of a production logging report for each time interval and accumulated oil and water rates. At the same time, the reservoir fluid sampling and sample analysis can be carried out repeatedly throughout the year at the customer’s request.

Part number:

Supplier:

GEOSPLIT Description

GEOSPLIT marked proppant is added to the ordinary proppant base mass, then is injected into the reservoir as a propping material during hydraulic fracturing.

Later, there is a long period (not less than two years) of gradual washing-out of the marker-reporters with water and oil. They are transported to the surface via reservoir fluid flow. Marker-reporters are segregated to both oil and water reservoir fluid phases

Production cycle

1

Coordination of the project scope of works and

sampling schedule with the Customer

2

Procurement of ceramic proppant,

incoming quality control

3

Synthesis of quantum marker-reporters

4

Production of marked proppant GEOSPLIT, output quality control, packaging and marking

5

Delivery of marked proppant GEOSPLIT to the Customer

6

Field quality control during multistage hydraulic fracturing operations

Multiple production logging in accordance with customer requirements

7

Sampling of the formation fluid, delivery to the GEOSPLIT

laboratory

8

Preparation and analysis of the samples

9

Interpretation of the data and issuance of production logging report for the customer

Later, there is a long period (not less than two years) of gradual washing-out of the marker-reporters with water and oil. They are transported to the surface via reservoir fluid flow. Marker-reporters are segregated to both oil and water reservoir fluid phases

Production cycle

1

Coordination of the project scope of works and

sampling schedule with the Customer

2

Procurement of ceramic proppant,

incoming quality control

3

Synthesis of quantum marker-reporters

4

Production of marked proppant GEOSPLIT, output quality control, packaging and marking

5

Delivery of marked proppant GEOSPLIT to the Customer

6

Field quality control during multistage hydraulic fracturing operations

Multiple production logging in accordance with customer requirements

7

Sampling of the formation fluid, delivery to the GEOSPLIT

laboratory

8

Preparation and analysis of the samples

9

Interpretation of the data and issuance of production logging report for the customer