|

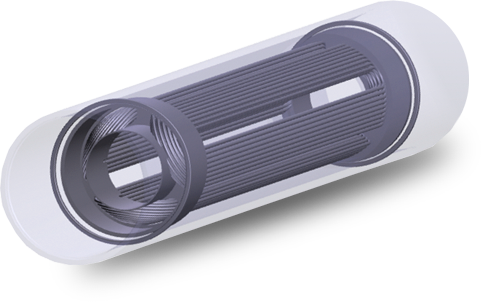

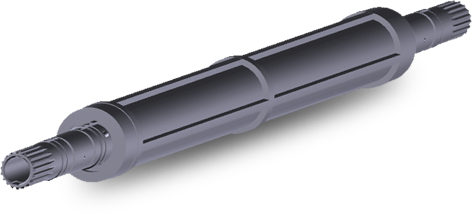

Lex Permanent Magnet Motor (LPM)

Lex Permanent Magnet Motor (LPM) Technology offers an advanced alternative to provide rotational energy for electrical submersible pumps. LPM offer a replacement of AC Induction Motor (AC) by Asynchronous PMM drived with universal VSD.

Part number:

Supplier:

LLC "Lex"Description

DOWNHOLE PM MOTORS WERE DESIGNED TO:

Increase downhole motor efficiency up to 93 %

Decrease cable losses by 25 – 40 %

Decrease surface equipment losses by 5 – 10 %

HIGHER EFFICIENCY

Permanent magnets in the rotor eliminate electric & magnetic losses involved with a “squirrel cage” in induction rotor

The stator flux penetrates only to the depth of the rotor magnets, unlike the induction motor

MINIMIZED DEGRADATION OF INSULATION

Achieved due to lower wasted heat amount and start-up current

LOWER TEMPERATURE RISE

No need to stop for cooling when ramping-up

Lower scaling risk

Lower requirements for seal temperature rating

Higher reliability and longer runlife

RELIABLE INTERMITTENT OPERATION

COMPACT DESIGN & HIGHER PASS-THROUGH DLS AVAILABLE

Achieved due to higher power density in rotor

Increase downhole motor efficiency up to 93 %

Decrease cable losses by 25 – 40 %

Decrease surface equipment losses by 5 – 10 %

HIGHER EFFICIENCY

Permanent magnets in the rotor eliminate electric & magnetic losses involved with a “squirrel cage” in induction rotor

The stator flux penetrates only to the depth of the rotor magnets, unlike the induction motor

MINIMIZED DEGRADATION OF INSULATION

Achieved due to lower wasted heat amount and start-up current

LOWER TEMPERATURE RISE

No need to stop for cooling when ramping-up

Lower scaling risk

Lower requirements for seal temperature rating

Higher reliability and longer runlife

RELIABLE INTERMITTENT OPERATION

COMPACT DESIGN & HIGHER PASS-THROUGH DLS AVAILABLE

Achieved due to higher power density in rotor