|

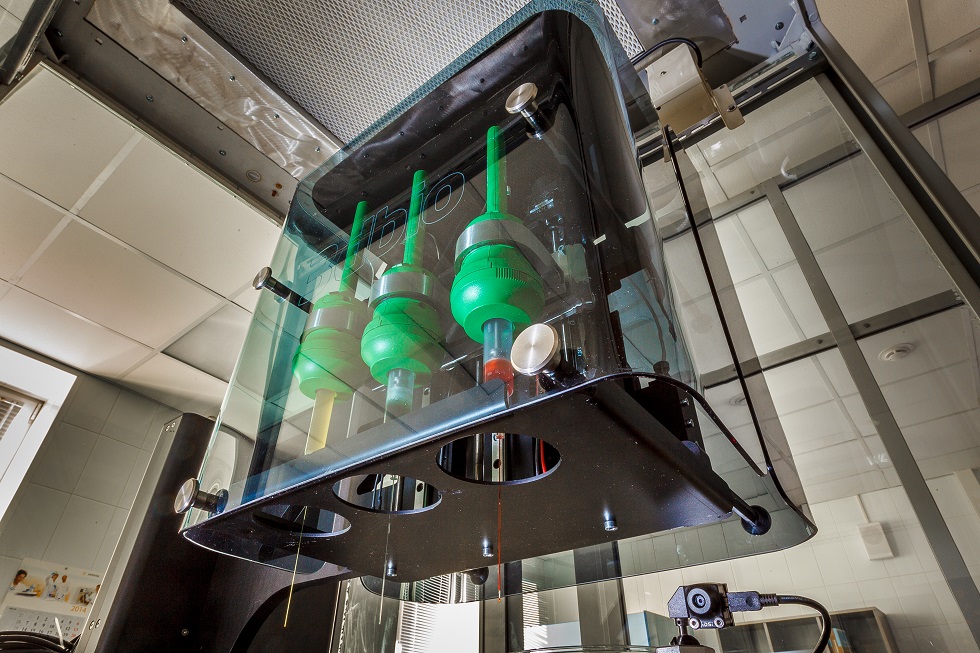

Bioprinter FABION

Bioprinter FABION

Unveiled by our Moscow, Russia-based subsidiary, 3D Bioprinting Solutions, in September of 2014, the originally designed FABION bioprinter allows precise layer-by-layer deployment of tissue spheroids (bioink) in hydrogel (biopaper) using a programmed digital model. The printing of spheroid layers, which may differ from each other, continues for the programmed number of times until the final layer is printed. This procedure allows creating live and functional 3D tissue and organ constructs with a complex structure.

Part number:

Bioprinter FABION

Description

Due to its unique design and proprietary engineering solutions developed by 3D Bioprinting Solutions, FABION is a truly universal tool for printing live and functional 3D tissue and organ constructs.

FABION is superior to other commercially available bioprinters in many respects:

• Multifunctionality: FABION allows printing with a wide range of hydrogels, using different types of polymerization (temperature, ionic, chemical, pH, etc.)

• Safety: A unique UV tool for hydrogel (biopaper) polymerization does not contact with spheroids or cells and, consequently, does not damage their DNA.

• Flexibility: FABION allows combining different methods of bioprinting, methods of application, and materials. Further enhancing the equipment’s flexibility is a wide range of programmable and software controlled parameters of bioprinting.

• Precision: FABION’s resolution meets the highest standards in bioprinting.

• Laser calibration system: Х-Y-Z positioning system has a feedback feature allowing the bioprinter’s nozzle positioning accuracy of 5 micrometers, thus ensuring a very precise reproduction of the programmed digital model.

• Compactness: Г-shaped design of the bioprinter’s printing system allows for sufficient space to accommodate nozzles.

• Control: 3D bioprinting is controlled in the real time mode with the help of an in-built digital camera.

FABION has a total of 5 nozzles with programmable capacity to dispense different types of bioink and biopaper. Three nozzles dispense bioink, and spheroids of any type or size, and various cells suspensions or other materials may be loaded into each of these three nozzles. The system allows setting the number of tissue spheroids to be dispensed, the thickness of printed layer, and other printing parameters for each particular nozzle. The other two nozzles are of a different design as they distribute biopaper, which may be applied by pulverisation or by dispensing.

The software developed for the bioprinter allows using different number of nozzles and in different configurations and is compatible with various 3D modelling programs and supports different polygonal modeling file formats. To launch the process of bioprinting, certain parameters are fed into the control software, such as:

• Distance between the centers of the spheroids.

• Positioning of spheroids in the coordinate grid.

FABION is superior to other commercially available bioprinters in many respects:

• Multifunctionality: FABION allows printing with a wide range of hydrogels, using different types of polymerization (temperature, ionic, chemical, pH, etc.)

• Safety: A unique UV tool for hydrogel (biopaper) polymerization does not contact with spheroids or cells and, consequently, does not damage their DNA.

• Flexibility: FABION allows combining different methods of bioprinting, methods of application, and materials. Further enhancing the equipment’s flexibility is a wide range of programmable and software controlled parameters of bioprinting.

• Precision: FABION’s resolution meets the highest standards in bioprinting.

• Laser calibration system: Х-Y-Z positioning system has a feedback feature allowing the bioprinter’s nozzle positioning accuracy of 5 micrometers, thus ensuring a very precise reproduction of the programmed digital model.

• Compactness: Г-shaped design of the bioprinter’s printing system allows for sufficient space to accommodate nozzles.

• Control: 3D bioprinting is controlled in the real time mode with the help of an in-built digital camera.

FABION has a total of 5 nozzles with programmable capacity to dispense different types of bioink and biopaper. Three nozzles dispense bioink, and spheroids of any type or size, and various cells suspensions or other materials may be loaded into each of these three nozzles. The system allows setting the number of tissue spheroids to be dispensed, the thickness of printed layer, and other printing parameters for each particular nozzle. The other two nozzles are of a different design as they distribute biopaper, which may be applied by pulverisation or by dispensing.

The software developed for the bioprinter allows using different number of nozzles and in different configurations and is compatible with various 3D modelling programs and supports different polygonal modeling file formats. To launch the process of bioprinting, certain parameters are fed into the control software, such as:

• Distance between the centers of the spheroids.

• Positioning of spheroids in the coordinate grid.

Specification

1. _3dbio_WEB_EN.pdf