|

Mathematical modelling

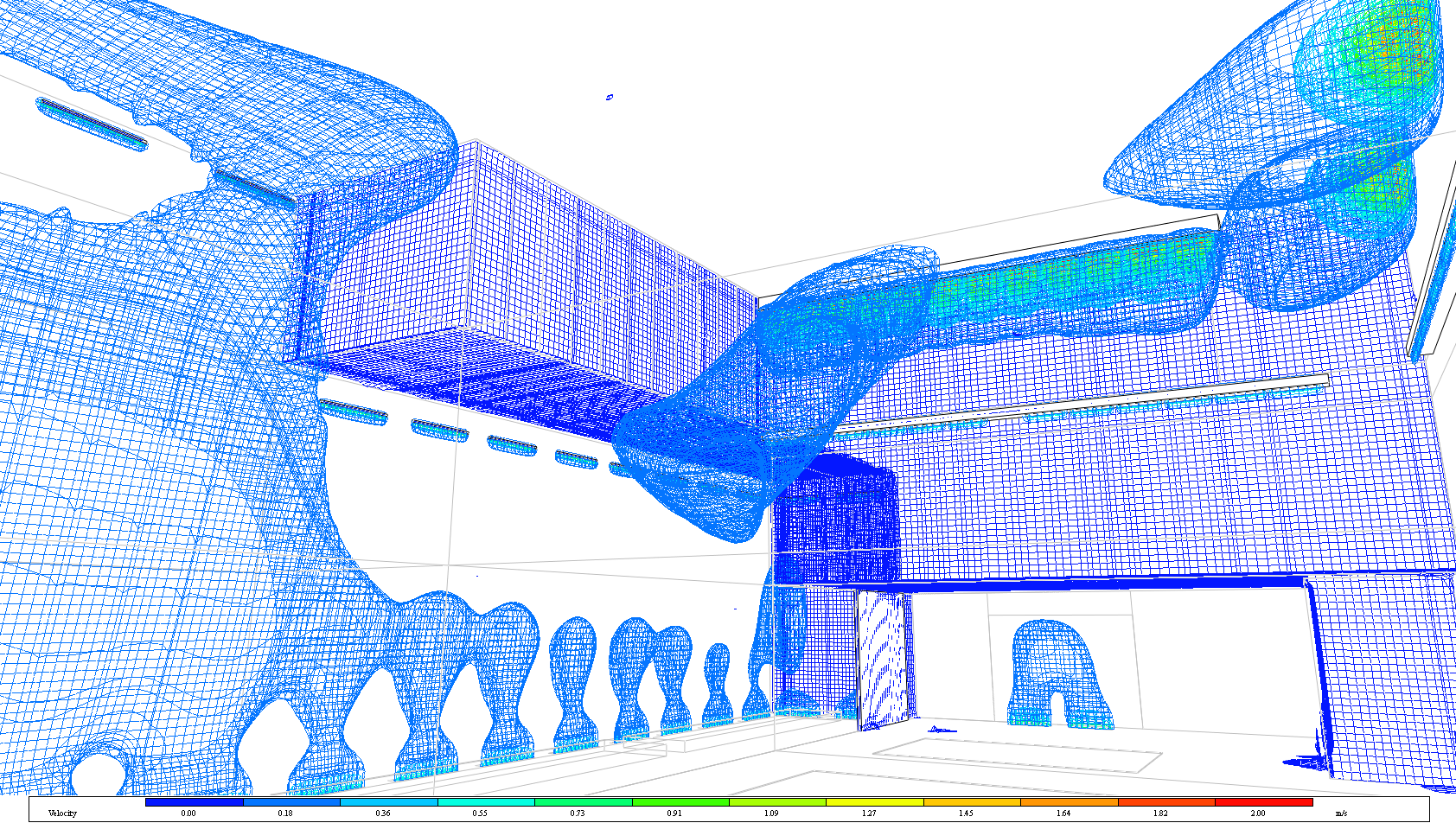

Modern capabilities of mathematical modelling make it possible to perform scientific research and engineering calculations of physical processes and technical systems via high-performance electronic computation.

Part number:

Description

Such an approach to the research and the design allows us to find the optimal parameters of equipment and devices within the shortest possible period of time. Moreover, mathematical modelling provides the possibility of studying of the nature of the process in aggressive environments. Also, it helps to identify the critical states of the system and the interrelationships of parameters for the development of automatic control systems as well as to conduct preliminary and final calculations for the development of laboratory and experimental-industrial equipment.

Qualitative mathematical modelling is directly linked to physical modelling and experimentation, however, even carrying out preliminary numerical simulation, allows to reduce the range of investigated parameters and variations of the system significantly and, as a result, to reduce time and material costs. In metallurgy, mathematical modelling becomes the only possible research tool, since most metals in liquid state have a high temperature and chemical aggressiveness for the work of the researcher and measuring equipment.

For more than 30 years of scientific and project activities RPC Magnetic hydrodynamics Ltd. has accumulated a unique practical and theoretical experience of electro-metallurgical processes researching. This experience made it possible to develop, implement and test the universal mathematical models of the melting-casting equipment, MHD-equipment and other equipment. Special analytical methods for calculating, modelling and designing of MHD-devices, proprietary algorithms and programs for two-way coupling of commercial numerical calculation programs, considering the peculiarities of metallurgical processes are the key capabilities and skills of company's experienced team. RPC Magnetic hydrodynamics Ltd. specialists regularly participate in the R&D works, and also in performing mathematical modelling of a full range of physical processes.

Qualitative mathematical modelling is directly linked to physical modelling and experimentation, however, even carrying out preliminary numerical simulation, allows to reduce the range of investigated parameters and variations of the system significantly and, as a result, to reduce time and material costs. In metallurgy, mathematical modelling becomes the only possible research tool, since most metals in liquid state have a high temperature and chemical aggressiveness for the work of the researcher and measuring equipment.

For more than 30 years of scientific and project activities RPC Magnetic hydrodynamics Ltd. has accumulated a unique practical and theoretical experience of electro-metallurgical processes researching. This experience made it possible to develop, implement and test the universal mathematical models of the melting-casting equipment, MHD-equipment and other equipment. Special analytical methods for calculating, modelling and designing of MHD-devices, proprietary algorithms and programs for two-way coupling of commercial numerical calculation programs, considering the peculiarities of metallurgical processes are the key capabilities and skills of company's experienced team. RPC Magnetic hydrodynamics Ltd. specialists regularly participate in the R&D works, and also in performing mathematical modelling of a full range of physical processes.