|

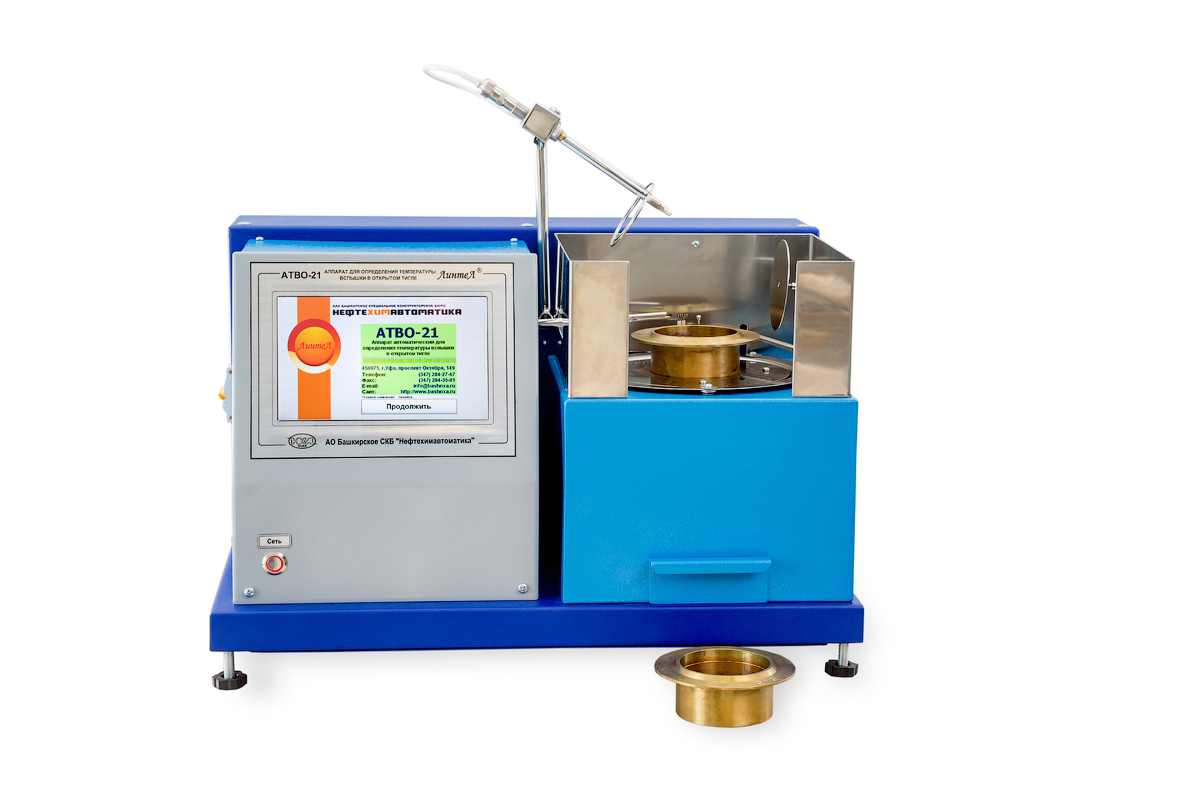

LinteL ATVO-21 Automatic open cup tester (with gas ignition) Cleveland method

LinteL ATVO-21

Automatic open cup tester (with gas ignition)

Cleveland method

Standards implemented

GOST 4333-2014

GOST 33141-2014

ASTM D-92

ISO 2592-73

Part number:

Description

The tester automatically performs heating of the product at a specified rate, testing its vapor using gas

ignition, flash detecting, introducing correction for atmospheric pressure, storing the result in non-volatile memory

Size of the flame ball is maintained automatically and is independent of gas pressure fluctuations

The tester resumes burning of the gas ball automatically in the event of its fading

The tester has a built-in gas leak detector. When leak detected, the tester switches off the gas and heater, and

gives an appropriate message

Integration with LinteL Link Data Collection System enables collection and transfer of laboratory test

results from the tester to a personal computer via wireless communication. Integration with the laboratory

information system LinteL LIS, provides a comprehensive automation of laboratory activities

Built-in pressure sensor for automatic introduction of correction for atmospheric pressure

Built-in fan for cooling the heater allows to proceed quickly to the next test

The log maintenance provides storage of up to 1000 test results (test method, product name, expected flash

point, flash point, barometric pressure, test completion date and time, operator).

Automatic test stop with sound signal about the test completion

The product overheating detection with automatic test completion

The burning product extinguishing at the end of the analysis by closing the cup with a lid

Universal inlet for connecting mini-cylinders

High-accurate product temperature sensor

Complete self-diagnosis system with fault indication on the display

Convenient intuitive menu for selecting the analysis program, navigation in the test log, diagnostics and

setup of the tester

Search of test result by parameters (test method, product name, expected flash point, flash point, test

completion date) using a filter.

ignition, flash detecting, introducing correction for atmospheric pressure, storing the result in non-volatile memory

Size of the flame ball is maintained automatically and is independent of gas pressure fluctuations

The tester resumes burning of the gas ball automatically in the event of its fading

The tester has a built-in gas leak detector. When leak detected, the tester switches off the gas and heater, and

gives an appropriate message

Integration with LinteL Link Data Collection System enables collection and transfer of laboratory test

results from the tester to a personal computer via wireless communication. Integration with the laboratory

information system LinteL LIS, provides a comprehensive automation of laboratory activities

Built-in pressure sensor for automatic introduction of correction for atmospheric pressure

Built-in fan for cooling the heater allows to proceed quickly to the next test

The log maintenance provides storage of up to 1000 test results (test method, product name, expected flash

point, flash point, barometric pressure, test completion date and time, operator).

Automatic test stop with sound signal about the test completion

The product overheating detection with automatic test completion

The burning product extinguishing at the end of the analysis by closing the cup with a lid

Universal inlet for connecting mini-cylinders

High-accurate product temperature sensor

Complete self-diagnosis system with fault indication on the display

Convenient intuitive menu for selecting the analysis program, navigation in the test log, diagnostics and

setup of the tester

Search of test result by parameters (test method, product name, expected flash point, flash point, test

completion date) using a filter.