|

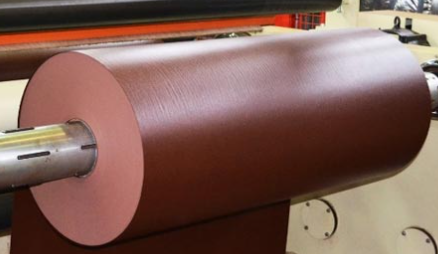

Phenolic Films

A phenolic film is a special type of kraft paper that has been impregnated with phenol-formaldehyde resin that includes pigments, dyes and various processing additives.

Depending on the density, the resin content in the product will be 63-67%.

Part number:

Supplier:

LLC "Innovative Technologies"Description

Phenolic films are used to create protective layers on the surface of plywood (rarer, chipboard and OSB) and to increase its resistance to aggressive external factors. The film is designed to be applied to the wood board’s facing by a hot pressing process. During this lamination, the resin contained in the film spreads over the plywood surface under a high temperature and pressure that causes it to penetrate into the pores and capillaries of the upper layer of the wood and create a smooth hard surface. To produce a corrugated surface, mesh wires or press pads are used during the pressing process. After the pressing, the ends of the plywood are covered with acrylic paint.

The laminated surface created by using the phenolic film prevents the penetration of moisture, and is highly resistant to abrasions, chemicals, fungus and mould formation, as well as to interactions with concrete, and it is easy to clean.

It is possible to apply the customer’s logo onto the produced film.

Main Types of Products:

To increase the wear resistance, as well as in cases of deep unevenness on the surface, several layers of film can be applied to the plywood during one pressing cycle, but this increases the required time for the surface curing.

Very deep defects on the plywood surface (knots, chips, cuts, etc.) should be filled with a heat-resistant wood putty and then laminated with a film after drying.

The most common colour of the film is dark brown, which is the main colour for the plywood forms. Productions of films in other colours and shades should be pre-agreed in accordance with the order volume and the availability of the dyes of the desired colour in stock.

A low-density film produced without the use of dyes is transparent after pressing, and the wood grain on the plywood surface can be seen.

Applications

Plywood laminated with the phenolic film is highly resistant to aggressive the environmental factors which can determine the areas of its application:

Reusable formwork in monolithic constructions (50-100 cycles of use)

Automotive industry

Car building

Interior and exterior decorations

Billboards and fences

Arrangement of sports and children’s playgrounds

Packaging

Bus stops

Agricultural buildings

The laminated plywood with a mesh or corrugated surface is used for the flooring in scaffolding or transport, and where a non-slip surface is required.

Manufactured Products

Density: 120- 300 g/m2

The phenolic film is available in densities of 120-300 g/m2. The density depends on the initial weight of the kraft paper (40-100 g/m2) used for the resin impregnation.

The higher the density of the phenolic film, the better the imperfections and irregularities on the plywood surface will be hidden during the pressing process, and the life cycle of the product consequently increases during various operations.

The laminated surface created by using the phenolic film prevents the penetration of moisture, and is highly resistant to abrasions, chemicals, fungus and mould formation, as well as to interactions with concrete, and it is easy to clean.

It is possible to apply the customer’s logo onto the produced film.

Main Types of Products:

To increase the wear resistance, as well as in cases of deep unevenness on the surface, several layers of film can be applied to the plywood during one pressing cycle, but this increases the required time for the surface curing.

Very deep defects on the plywood surface (knots, chips, cuts, etc.) should be filled with a heat-resistant wood putty and then laminated with a film after drying.

The most common colour of the film is dark brown, which is the main colour for the plywood forms. Productions of films in other colours and shades should be pre-agreed in accordance with the order volume and the availability of the dyes of the desired colour in stock.

A low-density film produced without the use of dyes is transparent after pressing, and the wood grain on the plywood surface can be seen.

Applications

Plywood laminated with the phenolic film is highly resistant to aggressive the environmental factors which can determine the areas of its application:

Reusable formwork in monolithic constructions (50-100 cycles of use)

Automotive industry

Car building

Interior and exterior decorations

Billboards and fences

Arrangement of sports and children’s playgrounds

Packaging

Bus stops

Agricultural buildings

The laminated plywood with a mesh or corrugated surface is used for the flooring in scaffolding or transport, and where a non-slip surface is required.

Manufactured Products

Density: 120- 300 g/m2

The phenolic film is available in densities of 120-300 g/m2. The density depends on the initial weight of the kraft paper (40-100 g/m2) used for the resin impregnation.

The higher the density of the phenolic film, the better the imperfections and irregularities on the plywood surface will be hidden during the pressing process, and the life cycle of the product consequently increases during various operations.