|

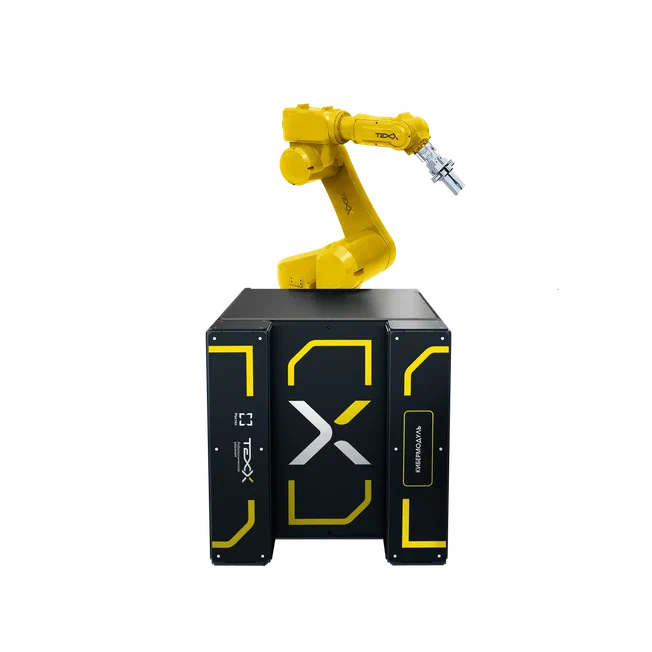

CYBERMODULE TKF

An effective solution for automating the loading and unloading of workpieces on CNC lathes and milling machines.

Part number:

0015448134

Price: 6 500 000 RUR

Supplier:

RT-TechpriemkaDescription

ROBOMODULE TKF delivers high performance and accuracy, reducing manual labor costs and defect rates.

Operator productivity increases by 2 to 4 times, with reduced labor expenses and fewer product defects.

Installation time at an operational facility: 5 to 10 working days.

The modular design allows easy adaptation to various tasks.

Main components of the system are manufactured in Russia.

The system includes:

Industrial robotic manipulator (6 axes, payload up to 50 kg)

Gripping system

Storage for blanks / finished products

Modular frame

Technical specifications:

Payload: 0.1 – 55 kg

Work speed: 15–20% higher than manual labor

Power consumption: 5–30 kW

Cell dimensions: 1200 × 800 × 1000 mm

Weight: 500 kg

Workpieces:

Disc shape ø > h:

Min. weight: 0.1 kg

Max. weight: 55 kg

Min. diameter: 20 mm

Max. diameter: 290 mm

Cylinder shape ø < l:

Min. weight: 0.1 kg

Max. weight: 25 kg

Min. diameter: 17 mm

Max. diameter: 235 mm

Compatible with machines from manufacturers:

DMG MORI, HAAS, SMEC, DOOSAN, TAKISAWA, Z-MAT, US WHEELER, TAISUN, CACTA, CMK, STANZA, SOLEX, JET, MAKINA, BLIN, DMC, STS, FEELER, METLEX, NINGBO, SPECTR, IRONMAC, SKMC, KMT, SKM, UNI.S, MUFENG, OTURN, DAS, BOCHI, SMICL, DMT, DMTG, PTG, KDA, DRC, ACL, HQT, JSWAY, HUZHENG, SUPER TURN, HEADMAN, DN SOLUTIONS, and others.

CYBERMODULE TKF is a ready-made solution to improve production efficiency and reduce manual labor costs.

Operator productivity increases by 2 to 4 times, with reduced labor expenses and fewer product defects.

Installation time at an operational facility: 5 to 10 working days.

The modular design allows easy adaptation to various tasks.

Main components of the system are manufactured in Russia.

The system includes:

Industrial robotic manipulator (6 axes, payload up to 50 kg)

Gripping system

Storage for blanks / finished products

Modular frame

Technical specifications:

Payload: 0.1 – 55 kg

Work speed: 15–20% higher than manual labor

Power consumption: 5–30 kW

Cell dimensions: 1200 × 800 × 1000 mm

Weight: 500 kg

Workpieces:

Disc shape ø > h:

Min. weight: 0.1 kg

Max. weight: 55 kg

Min. diameter: 20 mm

Max. diameter: 290 mm

Cylinder shape ø < l:

Min. weight: 0.1 kg

Max. weight: 25 kg

Min. diameter: 17 mm

Max. diameter: 235 mm

Compatible with machines from manufacturers:

DMG MORI, HAAS, SMEC, DOOSAN, TAKISAWA, Z-MAT, US WHEELER, TAISUN, CACTA, CMK, STANZA, SOLEX, JET, MAKINA, BLIN, DMC, STS, FEELER, METLEX, NINGBO, SPECTR, IRONMAC, SKMC, KMT, SKM, UNI.S, MUFENG, OTURN, DAS, BOCHI, SMICL, DMT, DMTG, PTG, KDA, DRC, ACL, HQT, JSWAY, HUZHENG, SUPER TURN, HEADMAN, DN SOLUTIONS, and others.

CYBERMODULE TKF is a ready-made solution to improve production efficiency and reduce manual labor costs.

.png)

.png)

.png)

.png)