Products

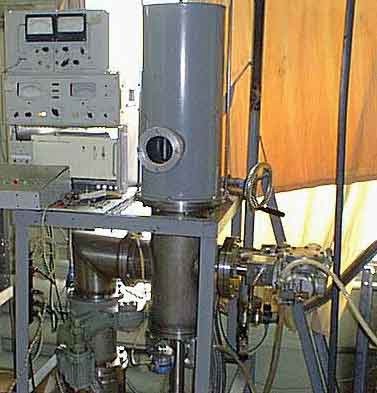

TECHNOLOGY FOR IMPROVEMENT OF STEELS PROPERTIES USING HIGH-CURRENT ELECTRON BEAMS PROCESSING

Supplier: The Ruselectronics holding company

Energy-saving high-efficiency heat treatment of steels and alloys products by accelerated electrons in air became possible due to development of accelerating technique and growth of electron accelerator power. This kind of heat treatment is called radiation-thermal processing (RTP). The RTP is innovative electron beam technology for metal products properties improving. Depth of electron energy release reaches up to 10 mm, so heating depth of metal without heat conductivity participation can be comparable with a working layer of a product. It allows to carry out heat treatment in a pulse mode and to obtain working layers on a surface of products with qualitatively new nanostructure of a material. Steels and alloys with such a structure possess high hardness and simultaneously raised impact elasticity

MANUFACTURE OF MAGNETIC TRANSMISSIONS FROM BAND AMORPHY ALLOYS

Supplier: The Ruselectronics holding company

Compact installation for irradiating materials with an electron beam

Supplier: The Ruselectronics holding company

Supplier: The Ruselectronics holding company

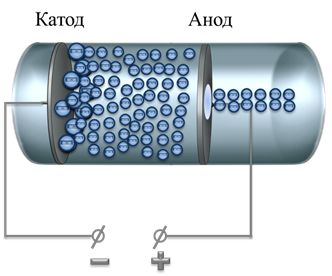

Installation of electrolytic deposition

Supplier: JSC “Radio Engineering Corporation “Vega”

Electrolytic deposition unit is designed for gold deposition on thin-walled copper conductors obtained

by vacuum deposition on substrates 48 * 60 mm.

Energy saving led light RZP-1103-30-3150

Supplier: JSC “Radio Engineering Corporation “Vega”

Office recessed prismatic led downlight RZP-1103-30-3150 – this is a new approach to light quality and energy saving, replacing the standard fixtures used for office lighting

.jpg)

.jpg)