|

Optical production

Optical production of the Ural Optical and Mechanical Plant offers services for the processing of optical components operating in the visible, UV and IR regions of the spectrum.

Part number:

Supplier:

Shvabe Description

Our production is equipped with the most modern equipment and instrumentation. We perform mechanical processing of details of any complexity, apply coating, form a topology, and perform assembly operations according to the customer's technical documentation requirements

JSC “PA “UOMP” various optical parts are manufactured: plates, prisms, lenses and others, including parts having aspherical surfaces, and parts having high radiation strength. Molding, grinding and polishing of optical parts is performed on modern precision numerical control machines using diamond tools. To obtain the required properties of parts in modern vacuum plants, optical coatings for various purposes are applied, including: antireflective, current-conducting, polarizing, mirror, beam-splitting, narrow-band filters and others.

Optical manufacturing also performs the production of precision optical scales by the method of reverse photolithography on modern equipment placed in clean rooms: circular optical scales (limbs), grids, linear scales, test tables, etc., which are used in geodetic instruments, special purpose products, control and adjustment equipment, etc. The photomasks of the optical scales are created using a laser image generator, also located in a clean room.

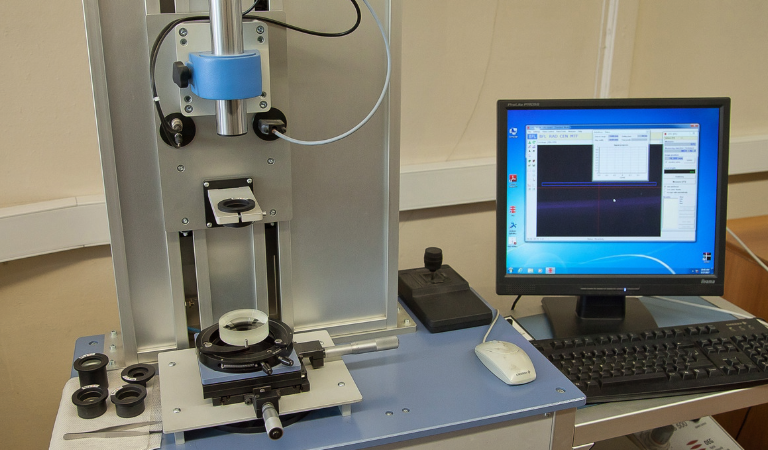

To control optical parts, modern instruments are used, including spectrophotometers, interferometers, goniometers, polariscopes, special stands.

Produced at JSC “Production Association “Ural Optical and Mechanical Plant” named after E.S.Yalamov”

JSC “PA “UOMP” various optical parts are manufactured: plates, prisms, lenses and others, including parts having aspherical surfaces, and parts having high radiation strength. Molding, grinding and polishing of optical parts is performed on modern precision numerical control machines using diamond tools. To obtain the required properties of parts in modern vacuum plants, optical coatings for various purposes are applied, including: antireflective, current-conducting, polarizing, mirror, beam-splitting, narrow-band filters and others.

Optical manufacturing also performs the production of precision optical scales by the method of reverse photolithography on modern equipment placed in clean rooms: circular optical scales (limbs), grids, linear scales, test tables, etc., which are used in geodetic instruments, special purpose products, control and adjustment equipment, etc. The photomasks of the optical scales are created using a laser image generator, also located in a clean room.

To control optical parts, modern instruments are used, including spectrophotometers, interferometers, goniometers, polariscopes, special stands.

Produced at JSC “Production Association “Ural Optical and Mechanical Plant” named after E.S.Yalamov”

Specification

1. Specification_RUS_ENG.DOCX